Let’s break down the failure of a garage floor coating—and how it could’ve been prevented with a true garage floor epoxy system.

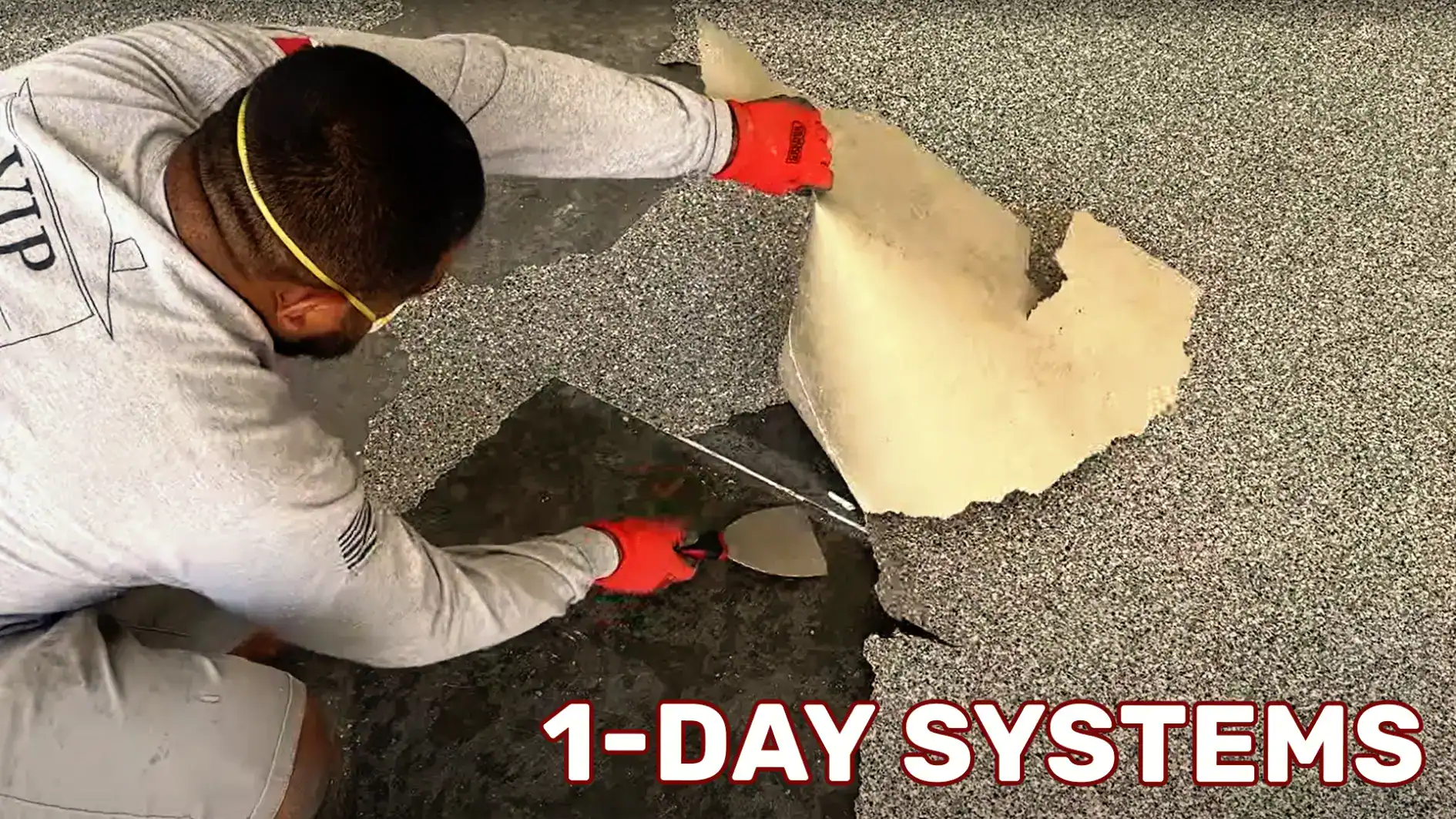

It starts off great. A Spokane-area homeowner hires a 1-day coating company that promises something big: “Our coating is 4 to 20 times stronger than epoxy!”. The installation is done by sunset, the floor looks glossy, and the marketing makes it sound bulletproof. But within months, there’s bubbling. Cracking. Peeling.

What happened?

Stage 1: A Strength Claim Without Context

“Stronger than epoxy” sounds impressive—until you realize it’s not comparing against professional-grade epoxy. It’s a comparison against water-based DIY kits, not the 100%-solids garage floor epoxy installed by trained pros.

These 1-day systems typically involve a fast-curing polyurea or polyaspartic applied directly to concrete. There’s no epoxy primer. No vapor barrier. No depth.

Stage 2: Moisture From the Ground Up

The Inland Northwest sees all four seasons—snowmelt, rain, and humidity can all lead to elevated moisture vapor beneath garage slabs. Even if a company tests for moisture, it’s meaningless if they don’t mitigate it.

Without a moisture-blocking primer, vapor slowly builds beneath the coating. The result? Bubbles, blistering, and eventual delamination.

Stage 3: The 1-Day Tradeoff

To complete a garage in a day, something has to go. Usually, that includes:

- Skipping the epoxy base coat

- Rushed or skipped flake buffing

- Only one topcoat (and often not 100%-solids)

These shortcuts create a thin, vulnerable system that doesn’t stand up to the temperature swings, vehicle wear, and seasonal moisture that Spokane garages endure.

Stage 4: Coating Failure Sets In

Within months, the glossy finish breaks down. The floor begins to peel. The owner is told, “It was probably moisture.” But what they weren’t told is that the system had no protection against it from the start.

And that “4 to 20 times stronger than epoxy” claim? Just marketing.

How Real Garage Floor Epoxy Prevents All of This

At Garage Floor Coating Inland NW, we install epoxy-based systems designed to last in Spokane’s climate. Our process includes:

- A 100%-solids epoxy primer for ASTM F3010-certified moisture mitigation

- A full-flake broadcast for durability and appearance

- Two coats of polyaspartic topcoat for chemical, UV, and abrasion resistance

That’s why we offer a lifetime warranty against moisture-related coating failure. The 1-day guys don’t—because they can’t.

Don’t fall for shortcuts or slogans. Contact Garage Floor Coating Inland NW today and get a garage floor epoxy install built to endure.