In the Inland Northwest, your garage isn’t just a place to park—it’s a workspace, a storage zone, and a buffer between the elements and your home. But without the right base coat, your garage flooring can fail faster than you think. At Garage Floor Coating Inland NW, we see the same problem again and again: coatings that don’t last because they start with the wrong foundation. That’s why we always start with garage floor epoxy.

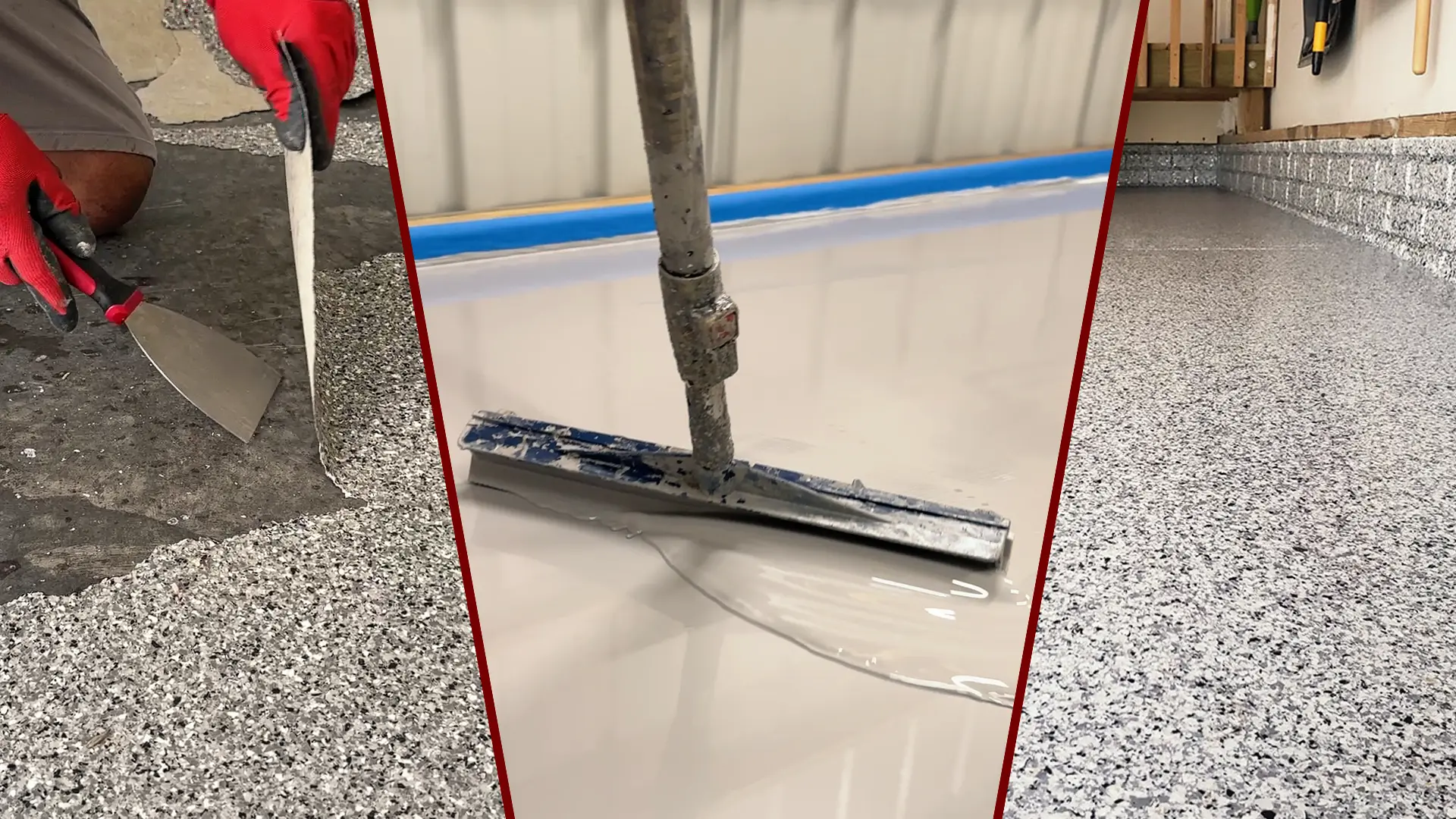

The Problem: Fast Installs That Don’t Hold Up

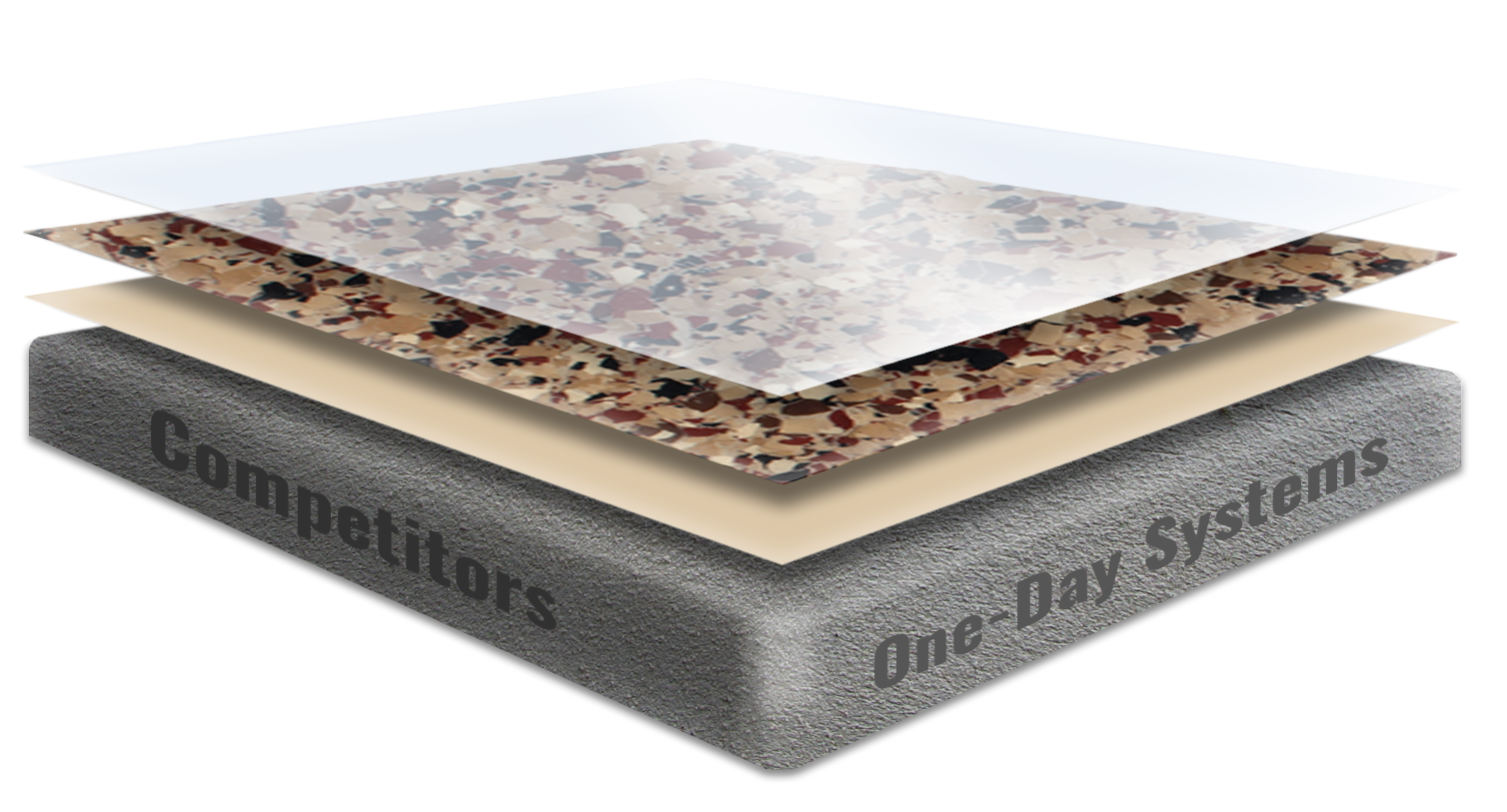

Many coatings on the market today are sold as “1-day” systems that use a quick-cure polyurea or polyaspartic for both the base coat and single clear topcoat. Installation of these coating systems is quick—in the promised one day. But speed can come at a cost.

- Polyurea and polyaspartic coatings cure very quickly (in under 1 hour). In the presence of humidity and/or medium to high concrete moisture, they cure even quicker. Too fast to deeply penetrate and properly bond with the concrete substrate.

- Concrete is porous and moisture wicks up creating hydrostatic pressures that push up on the coating system. The poorly-penetrating polyurea-polyaspartic base coat doesn’t offer strong moisture protection—an issue in Spokane’s wet winters and damp springs.

- Polyurea and polyaspartics, due to their chemistry, simple can’t be applied thickly. The thin, poorly-penetrating base layer is susceptible to moisture vapor transmission and high hydrostatic pressure.

This shortcut approach leads to problems like peeling, bubbling, and delamination—as early as one Inland Northwest winter.

The Solution: Garage Floor Epoxy That Bonds and Protects

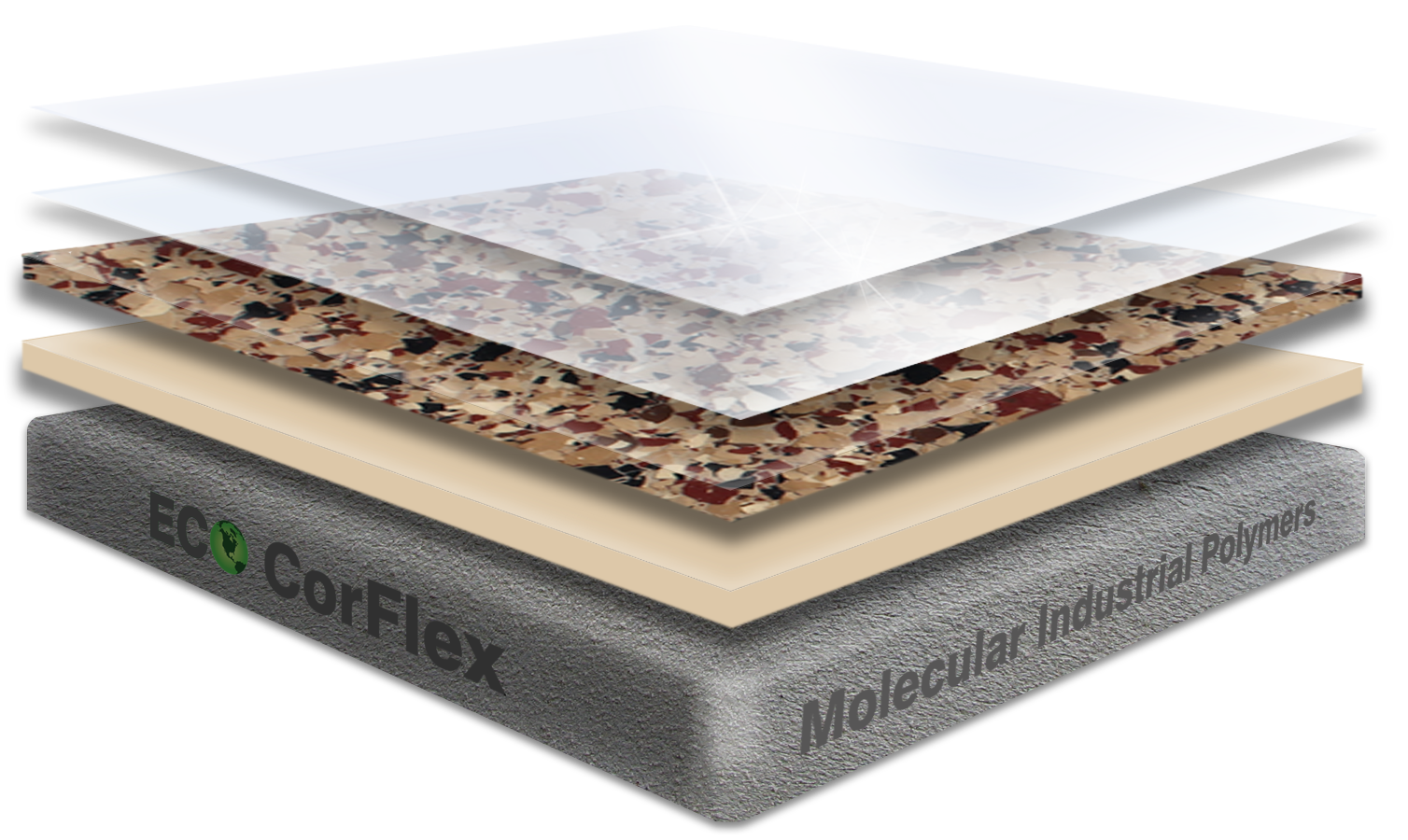

Using a moisture-mitigating, 100%-solids epoxy as the base coat (and saving the polyaspartic as top coat only) is the solution. Garage floor epoxy takes longer to cure. It allows the applied base coat to deeply penetrate into the concrete, creating a strong mechanical bond that can handle the demands of Inland NW garages.

The applied epoxy base coat acts as a moisture vapor barrier (MVB), providing dependable moisture mitigation. It prevents water vapor (and the resulting hydrostatic pressure) from pushing up through the slab, reducing the risk of bubbling and failure. And, because an epoxy goes on thicker than a polyurea-polyaspartic (epoxies are “high-build” coatings), it creates a durable base that holds up to real-world garage activity.

Why GFC Inland NW Gets It Right

At Garage Floor Coating Inland NW, our 2-day system includes:

- A slower-curing, high-build, moisture-mitigating, 100%-solids garage floor epoxy base coat for deep adhesion and moisture control

- Two (not just one) 100%-solids polyaspartic topcoats for UV, chemical, impact and stain resistance for a clean, lasting finish

Don’t risk your investment on a fast fix. Choose a garage floor system that’s built to handle the Inland Northwest—starting with the strength of epoxy.