When Labels Lie: What 1-Day Systems Don’t Tell You

In the Inland Northwest, Spokane homeowners deal with wide seasonal swings—snow and ice in winter, dry heat in summer, and year-round moisture concerns. So when a company offers fast “epoxy flooring” installation, it’s easy to assume you’re getting a tough, multi-layered system that will hold up through it all.

But here’s the catch: most 1-day systems advertised as epoxy flooring don’t use epoxy at all. They rely entirely on polyaspartic coatings and slap the word “epoxy” on the label because it sells.

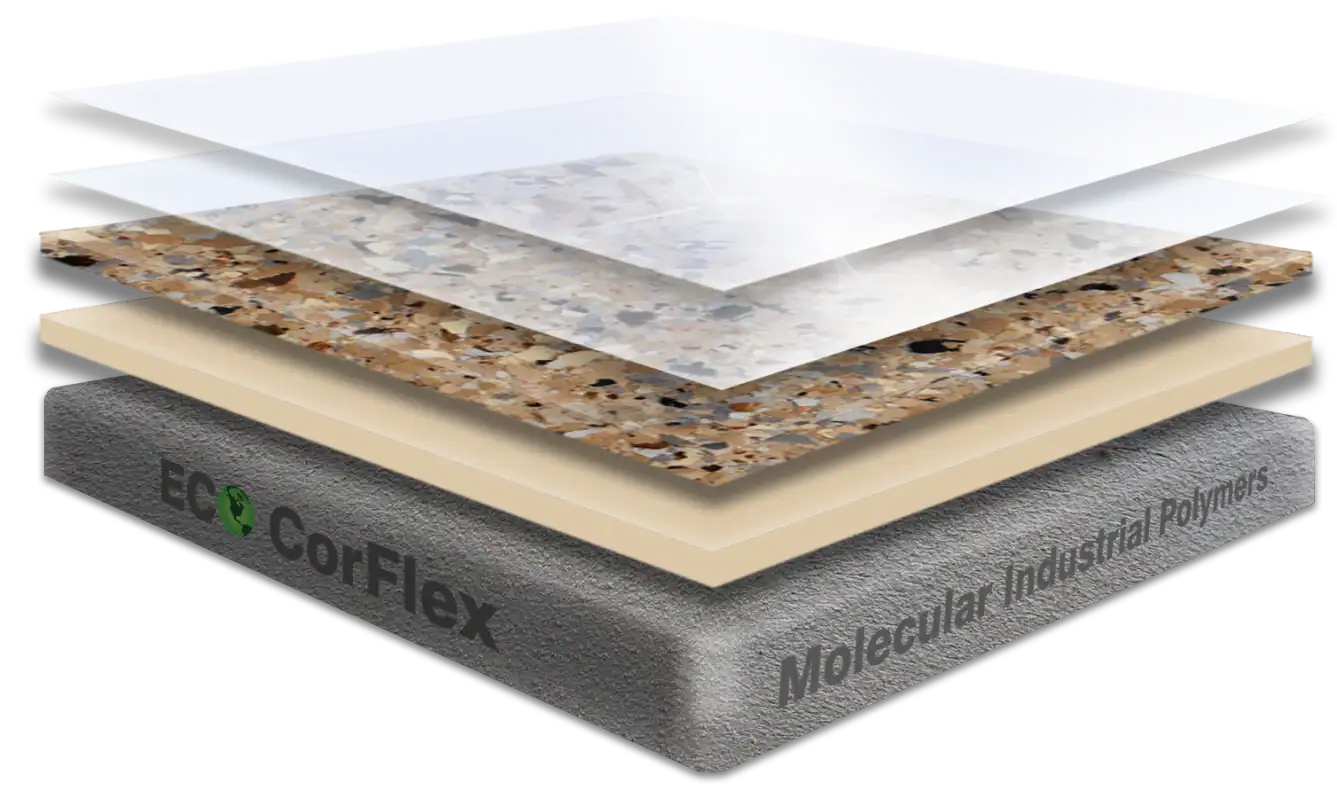

Let’s walk through the real anatomy of an epoxy flooring system—and what’s missing when shortcuts are taken.

Layer 1: Concrete Prep

To be fair, most companies—including 1-day outfits—do the mechanical prep step correctly. Grinding the surface is essential for proper adhesion. But that’s just the starting line. The real difference is in the chemistry layered on top.

Layer 2: The Base Coat

What GFC Uses: 100%-Solids Moisture-Mitigating Epoxy as the Base Coat

- Cures slowly and penetrates deeply into the concrete

- Creates a thick, structural base (epoxies are “high-build” coatings)

- Functions as a true moisture-mitigating coating, essential in Spokane’s damp spring and snowy winters

What 1-Day Systems Use: Polyaspartic or Polyurea Base Coat

- Cures rapidly (especially in the presence of moisture), limiting penetration into the slab

- Too thin for long-term protection (these coatings are not “high-build”)

- Offers poor performance against moisture-vapor pressure, leading to delamination or bubbling

Layer 3: The Top Coats

GFC’s System: Two Polyaspartic Topcoats

- Dual 100%-solids topcoats (not just one!)

- UV-resistant, stain-resistant, and easy to clean

- Provides long-term surface durability

- Complements the epoxy base coat for total system strength

1-Day Approach:

- Typically only one polyaspartic layer (less than 100%-solids)

- No epoxy foundation means limited durability

- May look nice at first, but often deteriorates faster in Spokane’s shifting conditions

Why Real Epoxy Flooring Matters in the Inland Northwest

With Spokane’s freeze-thaw cycles and moisture-rich soil, surface-level coatings just don’t cut it. You need a garage floor that won’t peel, bubble, or degrade when conditions change—and that starts with epoxy.

At Garage Floor Coating Inland NW, our 2-day, moisture-mitigating epoxy flooring system delivers real performance, from the concrete up. If your floor doesn’t start with epoxy, it’s not true epoxy flooring—no matter what the brochure says.

Contact us today for your free estimate and discover the strength behind every layer.